Overview

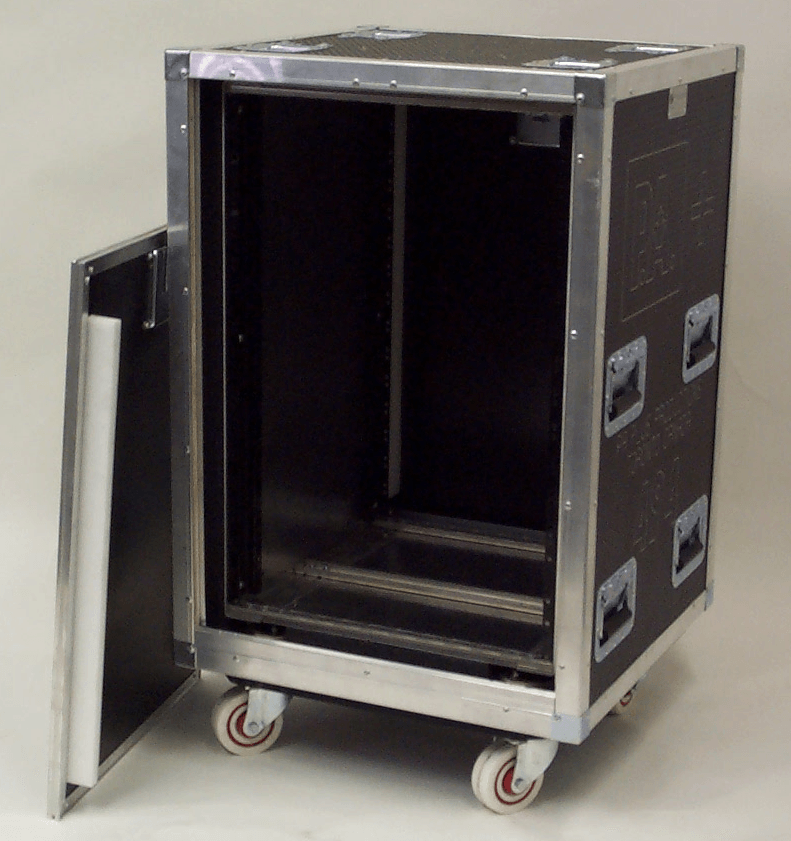

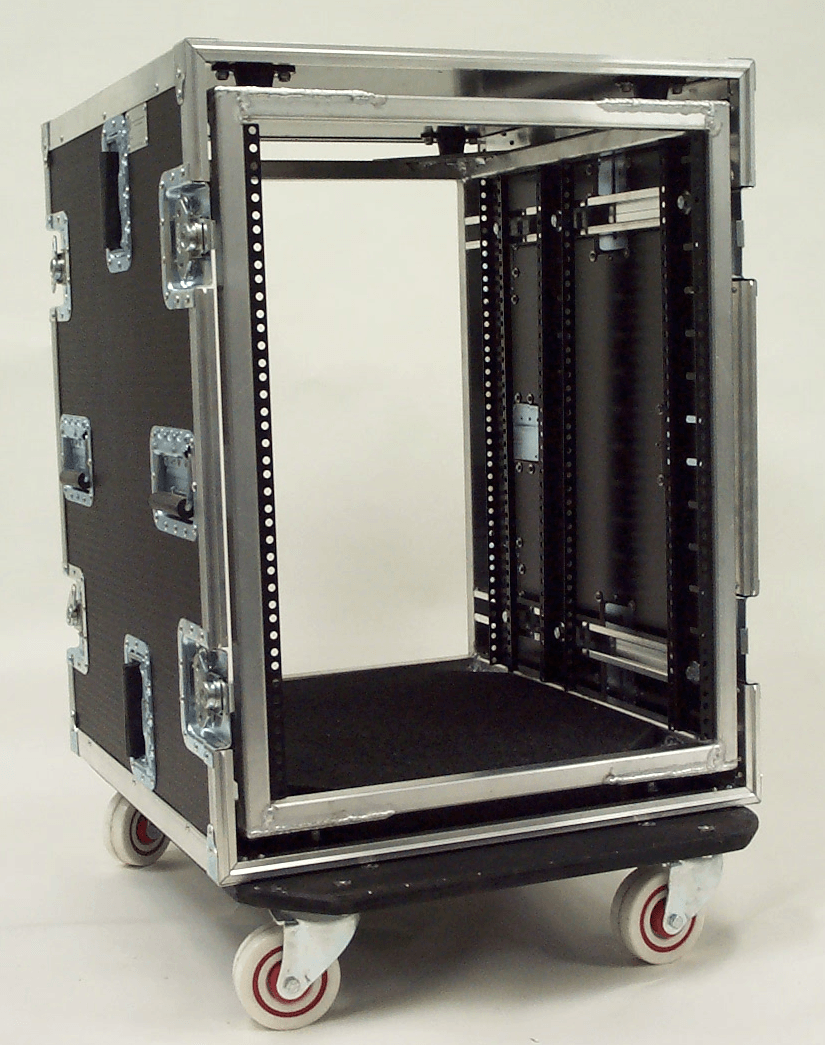

One type of case that has become a standard in the sound, lighting & music business, and the scientific & military communities, is the rack case. Rack-mount cases are available with or without an outer casing and has an industry-standard width faceplate designed to be mounted between rails. The purpose of this design is to allow mixing and matching of components to suit virtually any user requirement. For example, you may have a number of amplifiers that you want to house in the same enclosure along with signal processors, power conditioners or other related components. With rack-mount cases you can combine all of these in one convenient package. When the time comes to upgrade or change your configuration, you simply unbolt the old hardware and bolt in the new.

Rack Measurements

Rack heights are measured in “spaces”, a unit of measure equal to 1.75″. One space is termed “1U”.

The width of the rack mounting holes, centre to centre (between the rails), is an industry standard 18.375”.

“Rackable Depth” is the necessary distance from the front to the rear of the equipment.

Knowing the rackable depth and the number of spaces required allows you to specify the case that most precisely fits your requirements.

Customization of your Rack Case

Our ability to fabricate custom parts and components means that we can offer you sophisticated refinements that are unavailable anywhere else.

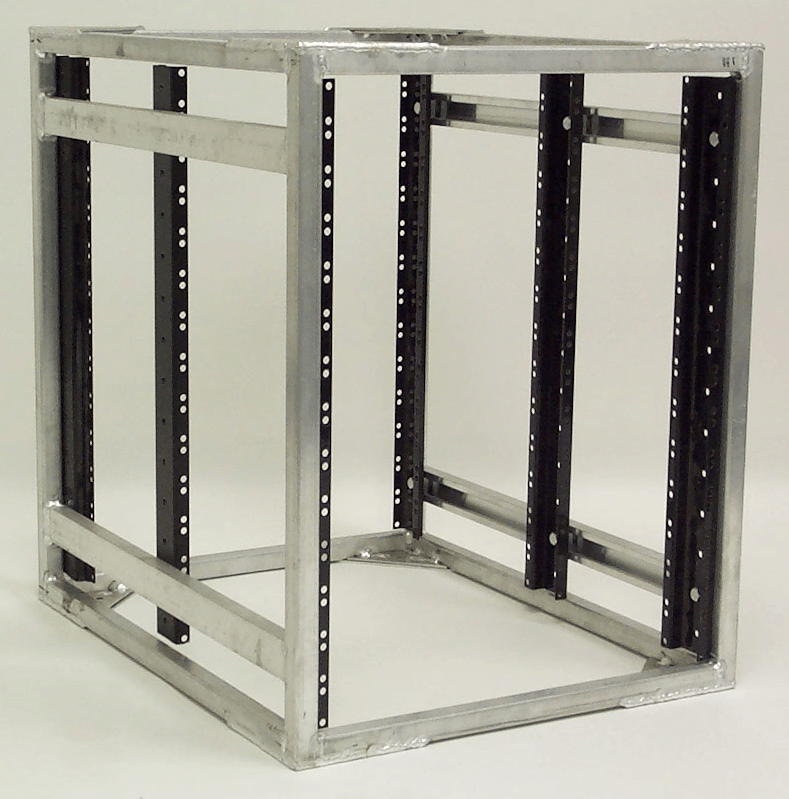

Front rack rails are installed as standard with optional mid and rear rails available also. Rails are adjustable to accommodate different equipment.

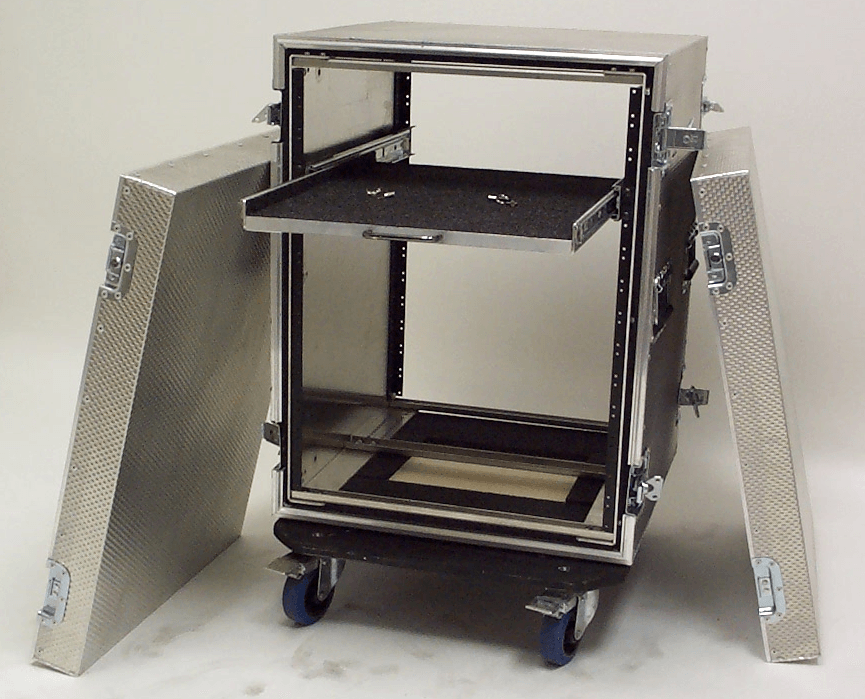

All of our rack-mount cases can be equipped with ventilating panels (or dishes), flanged electrical receptacles, fans, stacking hardware, fixed or removable caster boards, or drawers. Call or e-mail us with your equipment specs. We’ll design a rack-mount case that’s tailor-made for your application.

Standard Rack Mount vs Shock Dampening

Standard Rack Mount

Standard and shock mount racks differ only in the way that the rack mounting rails are fastened into the case. In a standard rack, the rails are attached directly to the case shell. In most situations, and for most equipment, a standard rack provides sufficient protection. Venue installations, in-house use or hand carried transport are all scenarios well suited to standard racks.

Shock Mounting

Extensive travel, delicately calibrated equipment or hostile shipping environments are examples of situations that warrant shock mounting. In these situations it is necessary to isolate the equipment from the case shell. We accomplish this by creating an inner sleeve that isolates your equipment from the outer case shell. A choice of either a foam lining or elastomeric isolators are used as the means of shock attenuation between the inner sleeve and the case shell.

Three Designs of Shock Dampening Rack Enclosures

Welded frames are the strongest construction method available for racks and are suitable for heavy to medium duty applications. We use 6061-T6 structural aluminum tubing for our welded frames. The use of elastomeric isolators provide the best choice of durometer (hardness) ratings for the optimal protection of your equipment when choosing this option.

A formed frame is a strong, less expensive alternative to welded frames and is also suitable for heavy to medium duty applications. At ECM our standard inner sleeve is constructed using 0.125″ thick 5052 aluminum sheet, the result is a sleeve that offers lighter weight and better rigidity than a steel equivalent.

Foam is an economical choice for shock dampening and is suitable for less severe shock environments and light duty applications.